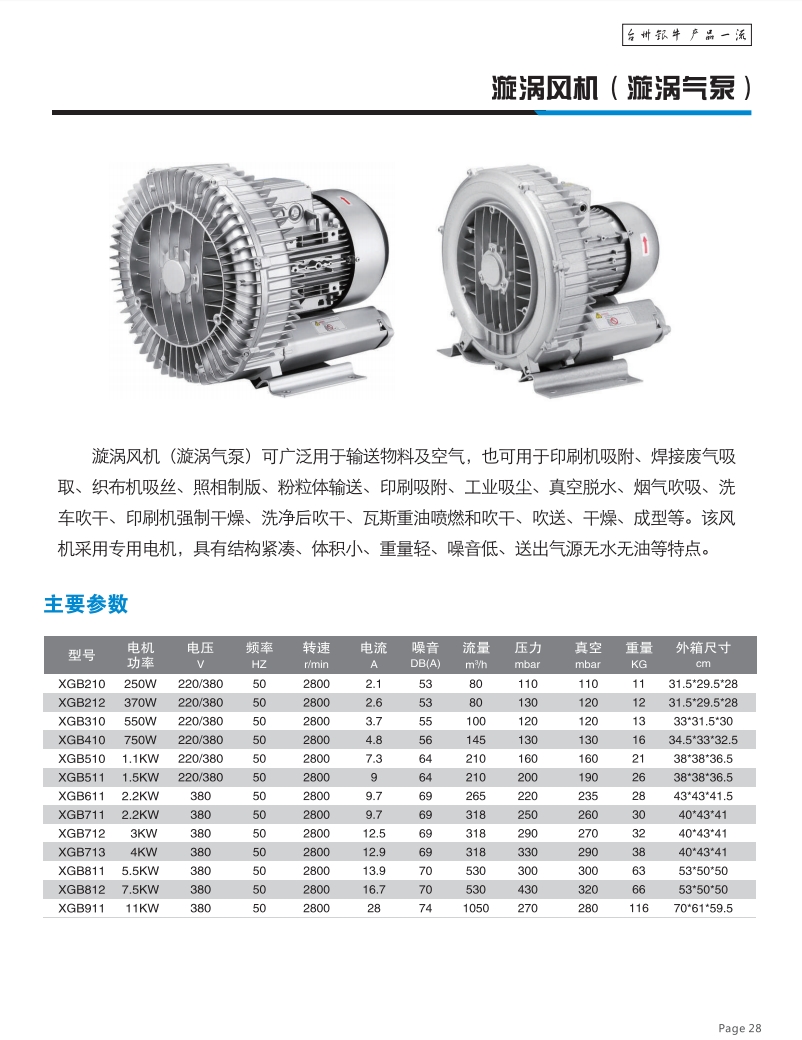

XGB Series Vortex Fan (XGB Series Vortex Air Pump)

Product profile

Vortex fan is a kind of high-pressure fan, also known as the ring fan. The impeller of the vortex fan consists of dozens of blades, which is similar to the impeller of a huge gas turbine. The air in the middle of the impeller blade is exerted by a centrifugal force and moves towards the edge of the impeller, where the air enters the pump body ring chamber and recirculates in the same way from the beginning of the blade. The circulating air flow generated by the rotation of the impeller leaves the air pump with extremely high energy for use. Vortex gas pump uses a special motor, compact structure, small volume, light weight, low noise, to send out the gas source without water without oil.

Use and scope of use

XGB series vortex fan is a kind of blow both ventilation source, it is mainly used in "paper cutter, combustion oxygen machine, coil filter forming machine, electroplating tank liquid mixing, atomization dryer, fish oxygen, water treatment, screen printing machine, photographic plate machine, automatic feeding machine, liquid filling machine, powder filling machine, electric welding equipment, film machinery, paper transportation, dry cleaning, dry cleaning clothes, air dust removal, dry bottle, gas transmission, feeding, collection, etc".

Use and maintenance

1. The fan should be placed in a relatively stable place, and the surrounding environment should be clean, dry and ventilated.

2. The rotation direction of the fan impeller must be consistent with the marked arrow on the fan shell.

3. When the fan works, the working pressure shall not be greater than the normal working pressure specified in the list, so as not to cause excessive heat from the air pump and the excessive current of the motor caused by the air pump damage.

4. Except for the two bearings of the motor rotor, other parts do not directly contact the friction. The fan bearing installation method is mainly divided into two types. The bearing of the first type of gas pump is installed in the pump between the motor seat and the impeller. This kind of gas pump usually does not need to add grease. The secondary air pump end bearings are installed in the middle of the pump cover and shall be carried out regularly loaded with grease (7018 high-speed grease). Once a month, the gas pump should increase the number of refueling. Maintenance of fan end of such air pump motor is type I air pump.

5. The filter screen at both ends of the inlet and outlet gas should be cleaned timely according to the situation to avoid the blockage and affecting the use.

6. The connection outside the inlet and outlet outlet must be hose connection (such as rubber pipe, plastic spring pipe).

7. Bearing replacement: Bearing replacement must be operated by a person familiar with the repair work. Unscrew the screws on the pump cover first, and then remove the parts one by one in the order shown. The removed parts should be cleaned, and then assembled in reverse order. When removing, the impeller can not be pried hard pry, apply special horse pull out, and do not miss the adjustment gasket, so as not to affect the good gap of the regulator when the factory. Before changing the bearing, the new shaft should be cleaned, dried and coated with no. 3 external lithium molybdenum dissulfide or 7018 to tell the grease. If the user is difficult in the operation. Should be sent to the factory for repair, do not randomly dismantle.

8. Solid, liquid and corrosive gases are strictly prohibited from entering the pump body.

Our service:

Marketing Service

100% tested CE certified blowers.Special customized blowers(ATEX blower,belt-driven blower) for special industry.Like gas transportation,Medical industry…Professional advice for model selection and further market development.Pre-sales service:

•We are a sales team, with all technical support from engineer team.

•We value every inquiry sent to us, ensure quick competitive offer within 24 hours.

•We cooperate with customer to design and develop the new products. Provide all necessary document.After-sales service:

•We respect your feed back after receive the motors.

•We provide 1years warranty after receipt of motors..

•We promise all spare parts available in lifetime use.

•We loge your complain within 24 hours.